Last month, I wrote 7 Things That Have Disrupted the Diamond Industry in the past 25 Years. Following on from this, below are five things that I predict will happen in the next 25 years.

3D Printed Jewellery

When: 15 to 25 years

If you don’t already know, the jewellery industry, like no other industry has been transformed by technology in the past 20 or so years. Nowadays, CAD/CAM manufacture is commonplace and jewellers around the world are creating pieces that that simply weren’t possible by hand. However, whilst the process is digital and much of it is automated, the last steps of jewellery manufacture – the casting, which is pouring the metal into a mould, along with final polishing and gemstone setting, is still done by humans.

Direct metal laser sintering (DMLS) solves this problem by 3D printing using metal. I first learned about DMLS about 10 years ago and thinking that lost wax and lost resin casting would be obsolete in the next decade. However, this certainly didn’t eventuate, but a recent article in Rapaport’s Jewelry Connoisseur told the story of US based jeweller Christian Tse, using machines from 3D printing company Desktop Metal. In the article, it is clear that the process of 3D printing jewellery is almost there, however, it certainly isn’t ready for the mass market. The article also describes Tse using robotic polishers, but, like with the 3D metal printer, the machines just aren’t quite perfect.

Above: A DMLS printer from Desktop Metal. Courtesy: Rapaport

My prediction is that like with a lot of technology, DMLS will linger within a small group of early adopters for years, or maybe decades, until something, or someone makes a breakthrough that both improves and reduces the price of the technology that makes it suitable for the mass market. Therefore, in the next 10 to 20 years, expect to see a lot more jewellery made by a 3D printer, and perhaps, even polished by robots.

Automated Diamond Grading

When: 5 to 10 years

Automated diamond grading is seen as the cure for over-grading, grading scandals and even as a way to speed up the grading process, and thus reduce the holding time needed whilst a diamond is being graded.

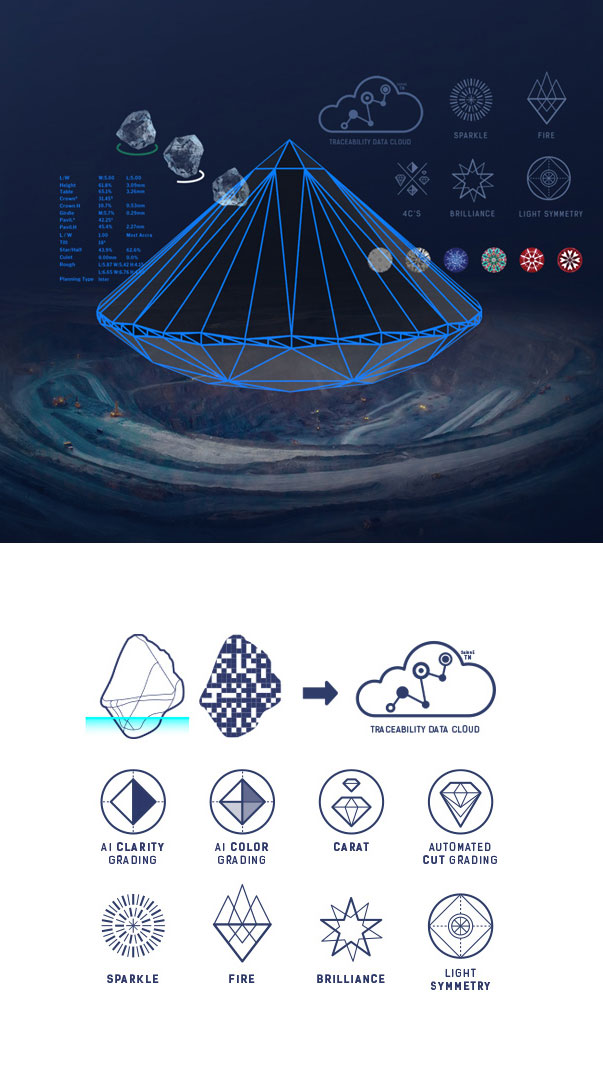

When you think about it, carat weight and cut is already graded with machines, so the logical step is to grade both colour and clarity with machines as well. Machines such as the Gran Colorimeter (which we own, but rarely use) have been around for decades, but they can be notoriously inaccurate. However, in the past five years, automated diamond has advanced in leaps and bounds. De Beers has opened a laboratory that uses machines names Falcon and Eagle in order to grade colour, fluorescence and clarity. Meanwhile, diamond technology and equipment maker, Sarine have developed machines that will grade colour and clarity, along with carat weight and light performance, supposedly using artificial intelligence. Sarine even purchased US based diamond grading laboratory GCAL this year in order to further promote their automated diamond grading system.

Above: Diagram showing GCAL automated diamond grading

However, the elephant in the room is the notoriously conservative GIA, who command upwards of 80+ percent of the diamond grading market share. It is highly unlikely that GIA will adopt any type of automated diamond grading, thus my prediction is that such grading will be limited to smaller diamonds, say below 0.25 carats, as well as supplemental certification that is done in addition to the GIA certificate to add value to and verification for the end consumer.

Lab Grown Diamonds Dominate

When: 1 to 3 years

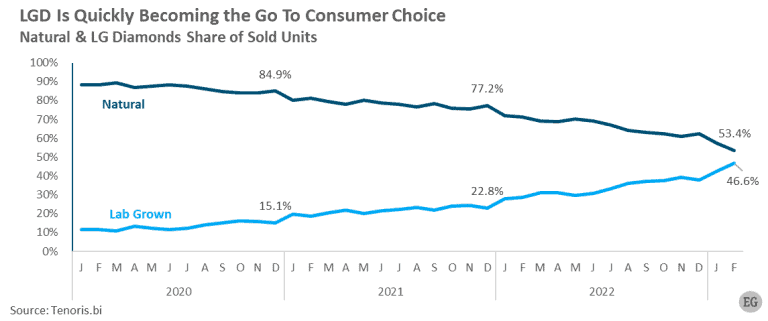

I’ve written about lab grown diamonds many times before, however, as of 2023, their market share compared to natural diamonds, is still less than natural diamonds. As Edahn Golan writes, the natural vs lab grown diamonds market share currently looks like this:

- 77.1% natural vs 22.9% lab grown in terms of value.

- 53.4% natural vs 46.6% lab grown in terms of units sold.

- 82.7% natural vs 17.3% lab grown in terms of diamond engagement rings.

Above: Natural vs lab grown market share in units sold.

As you can see, whilst lab grown will soon dominate in terms of general diamond jewellery, they still have a while to go to overtake natural diamonds in terms of diamond engagement rings. My prediction is that this that lab grown diamonds will overtake natural diamonds in terms of units sold within a year, and within three years, will overtake natural diamonds in terms of units sold for diamond engagement rings.

This will obviously cause problems for some in the diamond industry, as lab grown diamonds will cannibalise a portion of the natural diamond market. However, when finally forced to adopt lab grown diamonds, most in the diamond industry from manufacturers, all the way down to retailers will become more profitable.

Augmented Reality

When: 2 to 5 years

Augmented reality (AR) is currently not that common in the jewellery industry, despite being a fairly mature technology. Most commonly, AR is used to superimpose rings on peoples’ hands so they can try on a ring “virtually”. I think that AR is a great technology that reduces the need for retailers to keep a lot of stock and provides consumers with the opportunity to try on ring designs that they otherwise would not have been able to. However, only a few online retailers use it, and just recently, French jeweller Cartier announced it was trialling it in some of its stores.

Above: AR try on app from Trillion.

The main problem I have found is that no one has been able to render jewellery in these AR apps correctly, making the rings look almost “cartoon-like”. Sure, jewellery is difficult to render due to the way metal reflects light and the way diamonds transform light. However, as someone who designs jewellery and sends renders to clients every day, this should be an easy problem to fix, as there are many rendering programs that can render photo-realistic images. Once this challenge has been overcome, and AR apps “grow up”, expect widespread adoption throughout the industry.

Technology Built into Jewellery

When: 10 to 20 years

So-called, smart rings are nothing new, and typically have NFC chips in them used for contactless payments and access control, but are also used for health and fitness tracking as well. However, this technology hasn’t been adopted by the jewellery industry. This is probably because no one wants their engagement or wedding ring to track their every move, but also because the technology hasn’t matured enough to be able to fit into most modern day jewellery.

Above: Smart Ring from Oura

One application I can see being useful is for tracking down lost and stolen jewellery, in much the same way that Apple Airtags work. For this to happen, the technology needs to be small enough, that is under 2x2mm including battery, plus someone, most likely a phone manufacturer like Apple needs to either manufacture or licence the technology in order for widespread usage.

Whilst this seems to be a fairly inane use of technology, it should be remembered that millions of dollars of jewellery is either lost or stolen each year in Australia. Thus reducing this figure both reduces the cost of insurance and the heart ache of having jewellery stolen.

What About AI?

There’s been a lot of talk about artificial intelligence (AI) lately. However, a lot of this hype surrounds ChatGPT along with a myriad of competitors. My prediction is that AI will slowly make its way into the jewellery industry in ways such as an app to find out your finger size based on a photo, or design an engagement ring based on any number of parameters, such as star sign, favourite colour, favourite animal etc.

Overall, there’s a lot of technology that has been invented in the past 25 years that the diamond and jewellery industry is still in the process of perfecting or coming to terms with. Once ready, expect the technology such as DMLS and AR to revolutionise the way you buy jewellery.